Thermo Trolley

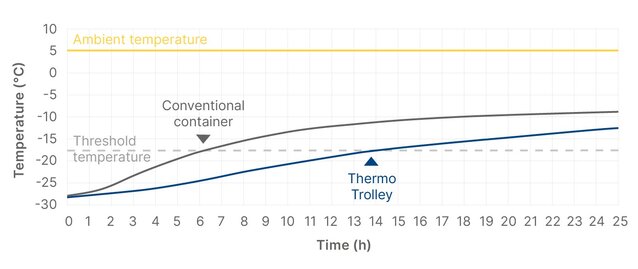

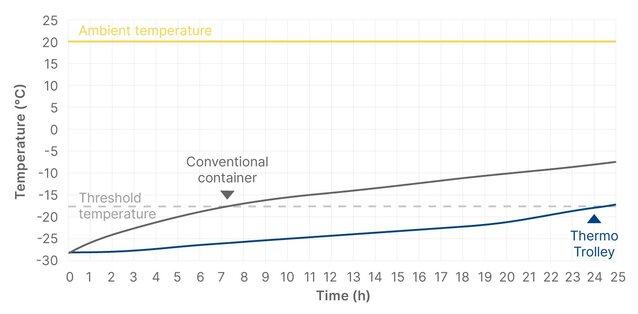

Reliable cold chain logistics with minimal operational effort

- No dry ice required

- Transport without refrigerated vehicles

- High in-store flexibility

The Thermo Trolley combines high-performance insulation with efficient logistics and a robust design to ensure the cold chain in food retail with minimal effort.

Your contact person