More than 1,000 employees at 57 locations – FEGA & Schmitt Elektrogroßhandel GmbH is one of the leading electrical wholesalers in central and southern Germany and primarily supplies industrial customers and the trades. FEGA & Schmitt has been part of the Würth Group for 25 years. In order to make transport from the central warehouse at the Heilsbronn site to the respective distribution centres more efficient, they selected Wanzl as one of their competent partners for intralogistics optimisation. "We want to get our shipments to the end consumer faster and, above all, in perfect quality. The environmental aspect is also a priority, as we want to use loading equipment that is reusable, not disposable. We are committed to saving on films and packaging of all kinds, process steps and going green," explains Roland Huber, Project Management Logistics at FEGA & Schmitt.

Optimisation of the logistics process with Wanzl parcel roll cages

In the process customary up to now, screens, lamps and refrigerators were packed daily on Euro pallets and wrapped with stretch film. The pallets were then picked up by various freight forwarders and transported to the respective regional distribution centre. From there, the packages were loaded onto the respective transporters. This will be optimised. In future, items from the central warehouse in Heilsbronn will be transported to the distribution centres in roll cages and racks. FEGA & Schmitt conducted research on loading equipment, which brought them to Wanzl. "We were impressed by the references and the diverse range. After contacting Wanzl Account Manager Anna Fischer, their customer service convinced us straight away," Huber confirms. The collaboration is also important to Wanzl. Cassandra Hieber, Product Management Digital Solutions Material Handling & Retail and Project Manager Asset Tracking, explains: "Wanzl acts as a solutions provider for optimising the entire shipping process, from concept creation, supplier screening in the partner network to project management, training of the customer’s employees and ultimately roll-out support". Wanzl's parcel roll cages provide FEGA & Schmitt with a solution for all their requirements. “Damage to the parcels is prevented, transport on the truck is possible in a space-saving manner, we save on packaging aids such as film, transport to the individual areas is faster and the process steps are streamlined,” says Huber. In addition, guard plates prevent damage to the castors when transporting with forklifts and the closed four-sided design ensures optimum load securing. The locking device prevents the cage from rolling away during loading and unloading. The load capacity is 500 kilograms.

Digital fleet management

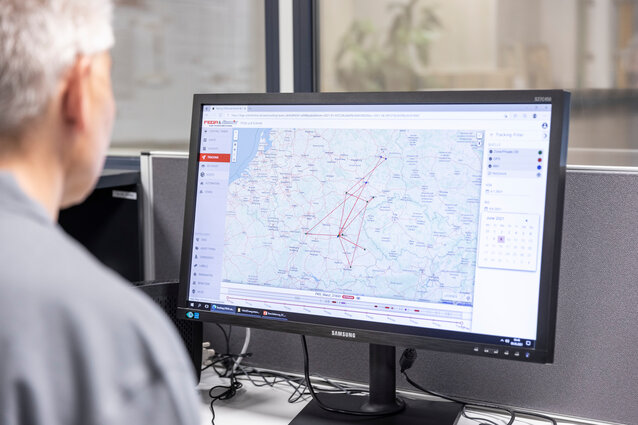

Furthermore, an asset tracking solution reduces the loss of entire containers and optimises the return of empties and inventory management. FEGA & Schmitt is the first electrical wholesaler in Germany to optimise its processes using tracking. Wanzl has equipped the roll cages with a tracker for this purpose. The principle of asset tracking is as economical as it is effective. A small tracker is attached to an asset (load carrier, roll cage or the goods themselves). This radio transmitter enables seamless tracking and analysis of the position and use of the asset – at any place at any time. Via a web application, shipping employees can access the data and, if necessary, initiate necessary measures. This data not only enables full control over the logistics process, it also forms the basis for the analysis and optimisation of delivery processes. The tracking takes place via the 0G-Sigfox network.

Once the goods have arrived at the right place, the empty roll cages are folded into an L-shape, pushed into each other to save space and sent back to FEGA & Schmitt. Thanks to the continuously monitored circulation system, the roll cages are safely returned to FEGA & Schmitt. "The advantage of the

tracking system is that we are always able to keep an eye on the loading equipment fitted with such a transmitter. Until now, all the loading equipment has not been returned reliably or it has been returned to us damaged. This has resulted in extremely high costs, as we have had to replace the loading equipment time and again. We can also track the availability of all load carriers in use . Asset tracking allows us to reduce expenses for new loading equipment by 75%," explains Huber.

Wanzl relied on its competent partner BOX ID Systems for the development and implementation of asset tracking. The Box ID System is a cost-effective all-in-one solution that uniquely enables FEGA & Schmitt to track, automate and optimise its cage and material flows both within the site and across borders. For this purpose, BOX ID Systems uses active tracking sensors lasting several years, which the load carriers can locate throughout Europe. In addition, they integrate further data from other identification technologies (e.g. QR/barcode, RFID, BLE, UWB, etc.) and combine them in one software. “This gives our customers an overview of the distribution of their logistics assets throughout the supply chain at all times. Manual inventory management is replaced by automatic and continuous inventory monitoring across all relevant locations. Critical processes and parameters are automatically monitored," says Christian Trösch, Head of Sales at BOX ID Systems.

Never lose a parcel roll cage again!

BOX ID Systems supplied FEGA & Schmitt with the complete tracking solution, consisting of tracking devices, cloud service and the special BOX ID Supply Chain Analytics software. They provided support in the implementation process, starting with the requirements analysis in joint workshops with the customer and implementation of a pilot project through to the final roll-out. "First of all, we analysed FEGA & Schmitt’s specific requirements in terms of tracking and the relevant KPIs and functions together with Wanzl Product and Project Management. On this basis, BOX ID configured the appropriate solution from hardware and the functions in the BOX ID Supply Chain Analytics Software," says Trösch. The focus was also on the production process at Wanzl, where the tracking devices and QR codes were installed on the cages during production. “Here we also developed processes and tools together to make assembly at Wanzl very flexible and easy,” says Trösch. Furthermore, FEGA & Schmitt employees can even record the status of a load carrier using a smartphone or other mobile end device by scanning a load carrier’s QR code. This forwards it to a web application where the status of the load carrier can be

managed, for example using a "Damage report", “Service/Repair” or a distinction between “Full” and “Empty” (empty goods identification). Photos of damaged load carriers or required spare parts, for example, can also be recorded in the web application, which makes spare parts management significantly easier.

Wanzl has already delivered a total of 400 parcel roll cages to FEGA & Schmitt. FEGA & Schmitt was extremely enthusiastic and intends to order around 800 other types of loading equipment with trackers for 2021/2022, such as parcel roll cages, lamp roll cages, long goods racks and system pallets. "We are very satisfied with the parcel roll cages, and are already planning and developing two new load carriers with trackers together with Wanzl. In principle, I now request all our logistical equipment from Wanzl – based on my excellent experience with them, among other things. The collaboration with Wanzl is exemplary. In fact, in my 30 years in logistics, I haven't met any other company that offers service like this. Thanks to Ms Fischer, Wanzl is always ready to support us, whether in planning and design or in implementation," says Huber enthusiastically.